Just How to Appropriately Maintain Your Ammo Depot for Long Life

Maintaining an ammo depot for durability includes a complex technique that prioritizes security, environmental control, and meticulous inventory administration. Managing climate problems and guaranteeing proper product packaging are crucial to protecting the integrity of the ammo.

Selecting the Right Storage Place

When choosing a storage area for your ammunition depot, it's essential to prioritize security and ease of access. The picked site must be certified with local guidelines governing the storage space of unsafe materials, making certain that it fulfills all safety criteria. Select an area that is away from populated locations, decreasing threat in the occasion of a mishap.

Access is another important factor to consider. The depot needs to be positioned near vital supply paths to facilitate reliable transport of ammunition, while additionally being protected enough to prevent unapproved gain access to. A well-planned accessibility route enables for risk-free loading and discharging, reducing the risk of injury or damage.

Additionally, consider the physical qualities of the site. Ground stability is vital; stay clear of areas prone to flooding or erosion, which might jeopardize the stability of your storage space. All-natural obstacles can boost security, so websites bordered by fences, walls, or natural landscapes need to be chosen.

Controlling Environmental Problems

Efficient control of environmental problems is essential for the preservation and dependability of stored ammunition. Factors such as moisture, temperature, and air top quality play a crucial function in keeping the honesty of ammo over time.

To accomplish these conditions, use climate control systems such as air conditioning and dehumidifiers. Regular monitoring of temperature level and moisture degrees with adjusted instruments is recommended, permitting timely modifications to keep ideal conditions. Additionally, ensuring appropriate ventilation can minimize the buildup of damaging gases that may jeopardize the ammunition.

Moreover, it is important to keep the storage area clean and complimentary from contaminants, which can promote deterioration and other kinds of deterioration. Utilizing bug control actions will certainly also help stop problems that can harm packaging and honesty. By consistently managing environmental conditions, the durability and reliability of your ammunition depot can be dramatically enhanced, making certain preparedness and effectiveness when required.

Regular Stock Management

Regular stock administration is important for making certain the operational preparedness of an ammunition depot. This process entails methodically tracking the amount, problem, and location of all ammo stock. Consistent stock checks help recognize any type of disparities in between real and taped supply degrees, which can indicate issues such as misplacement, degeneration, or theft.

Executing a structured stock administration system, such as a digital monitoring program, boosts precision and efficiency. Frequently arranged audits-- carried out quarterly or month-to-month-- permit for comprehensive assessments of stock and can reveal potential hazards or shortages in advancement. It is necessary to preserve in-depth documents that consist of set numbers, expiry days, and maintenance history to help with quick retrieval and compliance with safety policies.

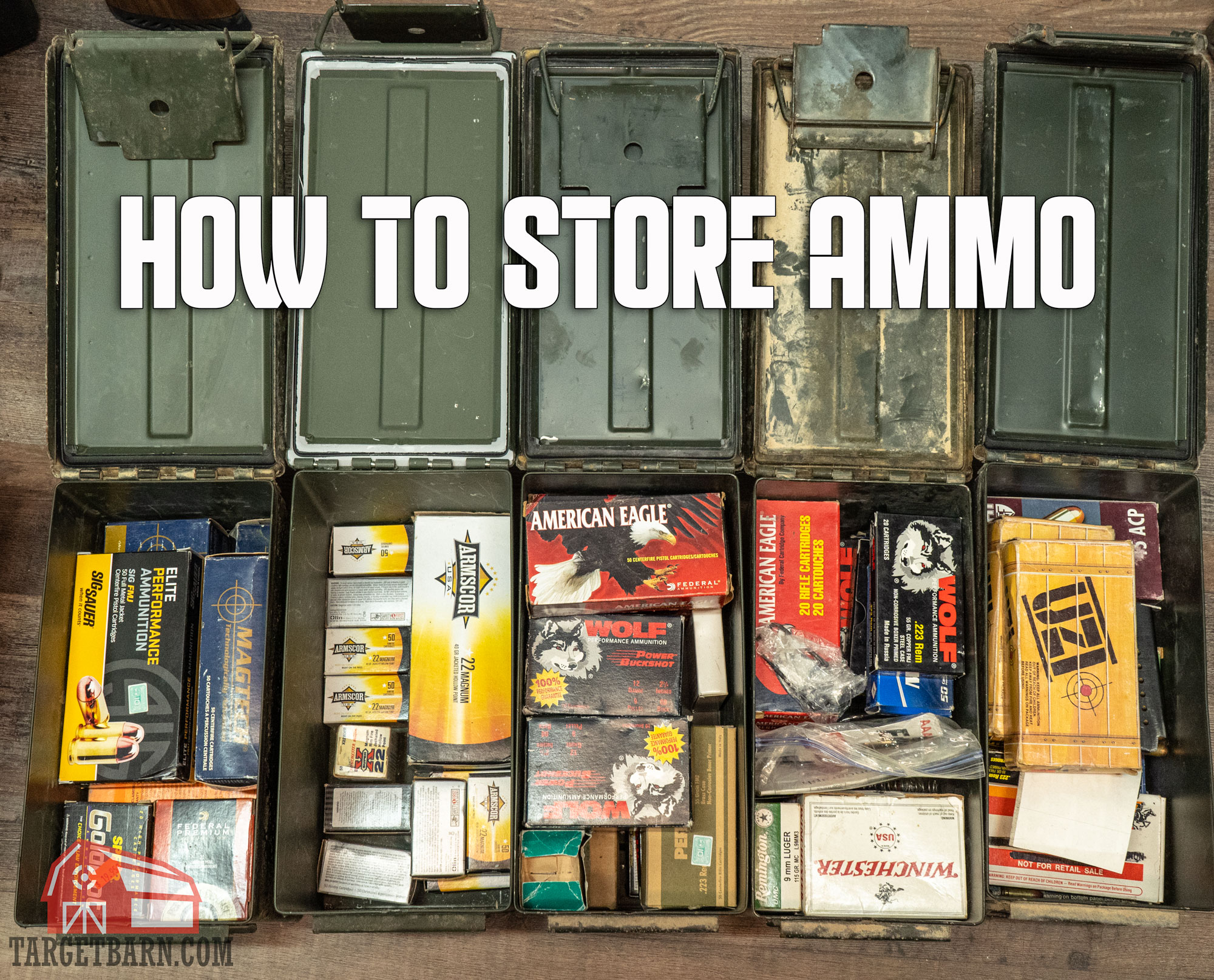

Making Sure Appropriate Packaging

Maintaining correct product packaging for ammo is an essential facet that matches efficient inventory monitoring. The stability of ammunition packaging plays a vital duty in making sure the safety, reliability, and long life of the kept materials. Making use of appropriate product packaging materials, such as moisture-resistant containers or sealed plastic bags, can dramatically alleviate the risks of deterioration brought on by environmental variables.

Each bundle should be plainly identified with important information, consisting of caliber, kind, and expiration days. This method not only assists in efficient supply tracking yet likewise boosts security by preventing the unintended use of obsolete or inappropriate ammo. Furthermore, using stackable and resilient containers can optimize storage room while lessening the risk of physical damage.

Appropriate product packaging prolongs the life of ammo and makes certain that it continues to be in optimal condition for use when needed. Adhering to these guidelines will aid keep operational readiness and promote safety within the ammunition depot.

Conducting Regular Inspections

To carry out efficient routine evaluations, develop a comprehensive checklist that covers crucial aspects such as storage problems, product packaging stability, and stock accuracy. Pay particular focus to ecological aspects, including temperature and humidity, which can considerably affect the stability and safety and security of ammo. Evaluate the physical condition of storage containers and guarantee that they have a peek at this website are devoid of corrosion, leakages, or damages.

Furthermore, assess the organization of the depot to facilitate very easy accessibility and precise tracking of supply. This company lessens the danger of mishaps and guarantees efficient access during functional demands. Paper all findings meticulously, keeping in mind any type of discrepancies or concerns that need immediate focus. Establish a protocol for resolving determined issues, consisting of timelines for resolution and accountable employees.

Conclusion

In verdict, effective maintenance of an check these guys out ammo depot demands mindful factor to consider of numerous elements. Selecting an ideal storage space place, managing environmental problems, conducting routine stock monitoring, guaranteeing correct packaging, and executing routine evaluations are all essential components. By adhering to these guidelines, the durability and security of the ammo depot can be significantly enhanced, ultimately adding to the dependability and performance of procedures while guarding workers and the surrounding setting.

Keeping an ammo depot for long life entails a complex approach that prioritizes safety, ecological control, and thorough supply monitoring.When picking a storage space area for your ammo depot, it's critical to focus on safety and security and availability. By continually taking care of ecological problems, the durability and dependability of your ammunition depot can be considerably enhanced, ensuring readiness and efficiency when needed.

Routine inventory administration is essential for making certain the my company operational preparedness of an ammo depot. Bulk Ammo Online. A culture of watchfulness and integrity in supply monitoring not just safeguards resources yet additionally enhances the overall reliability of the ammo depot, eventually supporting goal preparedness and operational efficacy